Been a while, sorry about that. I have been spending a lot more time on life and housework and have not had as much time for A&S. Still managed to fire up the forge to help a friend out. Mistress Amie Sparrow has been working on a Anglo Saxon pouch and contents. For this project she needed a forged iron nail and then needed a forged iron ring for the purse itself. The documentation for the nail can be found here:

And here is a photo dump of the process:

The next item needed for the Anglo Saxon pouch was the ring for the opening. This type of purse was worn on the belt and had an iron ring sewn in the mouth which would keep it closed until you needed to get in. For this I needed to make her 2 rings total, 1 for the purse she was making for herself, scaled to her design and a 2nd one as close to the original as possible. The documentation is not complete for this yet, but will be able to be found here:

And here is the photo dump for this project:

The 2nd ring was forged yesterday (6/14/21) in a grand fit of forging. This was the first time in quite a while that I was able to spend most of a full day in the forge. After a little clean up, I decided to light my forge. Reaching for my shovel to move the coal around, I realized that I had loaned the shovel to the outdoor kitchen. Presto, my first project of the day.

Just a utility tool and I forgot to take any pictures of it. I might try and add one in later. Sorry about that.

The next project was one that I had burning in the back of my head for a while, and it seemed like a perfect time to get to it. I decided to make an outdoor kitchen tool hanging rack. This would be a stand alone rack for the tools and utensils I have been forging for our Pennsic fire table. I am also working on a permanent fire table for Grimmsfield, so this is the first of 2 that I will be making. Because this was my own design and not modeled after something historical, and because I was just in the mood to forge without distractions, I only have pictures of the final project. This is one of my best pieces I have made so far. Every thing I planned, came out the way I wanted it to. Here are some pictures of it up on the range:

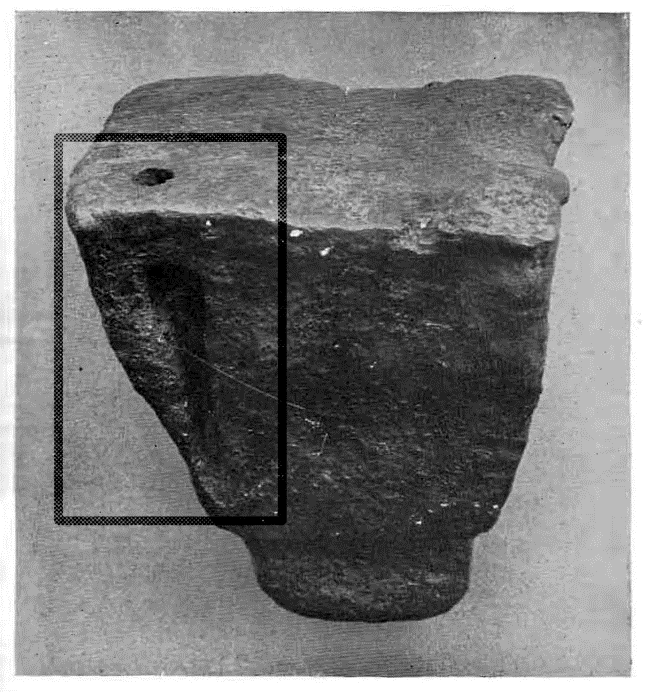

The last thing of interest that I have been working on is a modification of an old Bear Bow for my friend Miles. Often, old Bear recurves come with a built in sight for target shooting. These are not allowed at SCa shoots and the bow need to be modified before using in the SCA. Here is a picture of the sight:

In the past I have just cut a brass plate to cove the hole created by removing the sight and this has worked very well. On this bow I decided to push it a little further:

the plate is brass and the backing is vinyl to keep the elements from ruining it.

Well, that’s about all that I have been working on recently. I have 2 weeks open to close coming up., so I am not sure when I will be able to get back to the forge. Plus, I am beginning to see arrows come in that need fixing, bowstrings to make, and now a crossbow to rebuild.

I will write more soon.

Your servant,

Grimm