Well, once again I don’t seem to be keeping up on all of this the way I wanted. Back to working more and playing less, so not as much to write about. Reaching back to my last post and seeing what has happened since then. Not sure how much I feel like writing right now, but here are a few quick notes of the highlights:

I was persuaded to display at KASF.

Here is a gallery of my display:

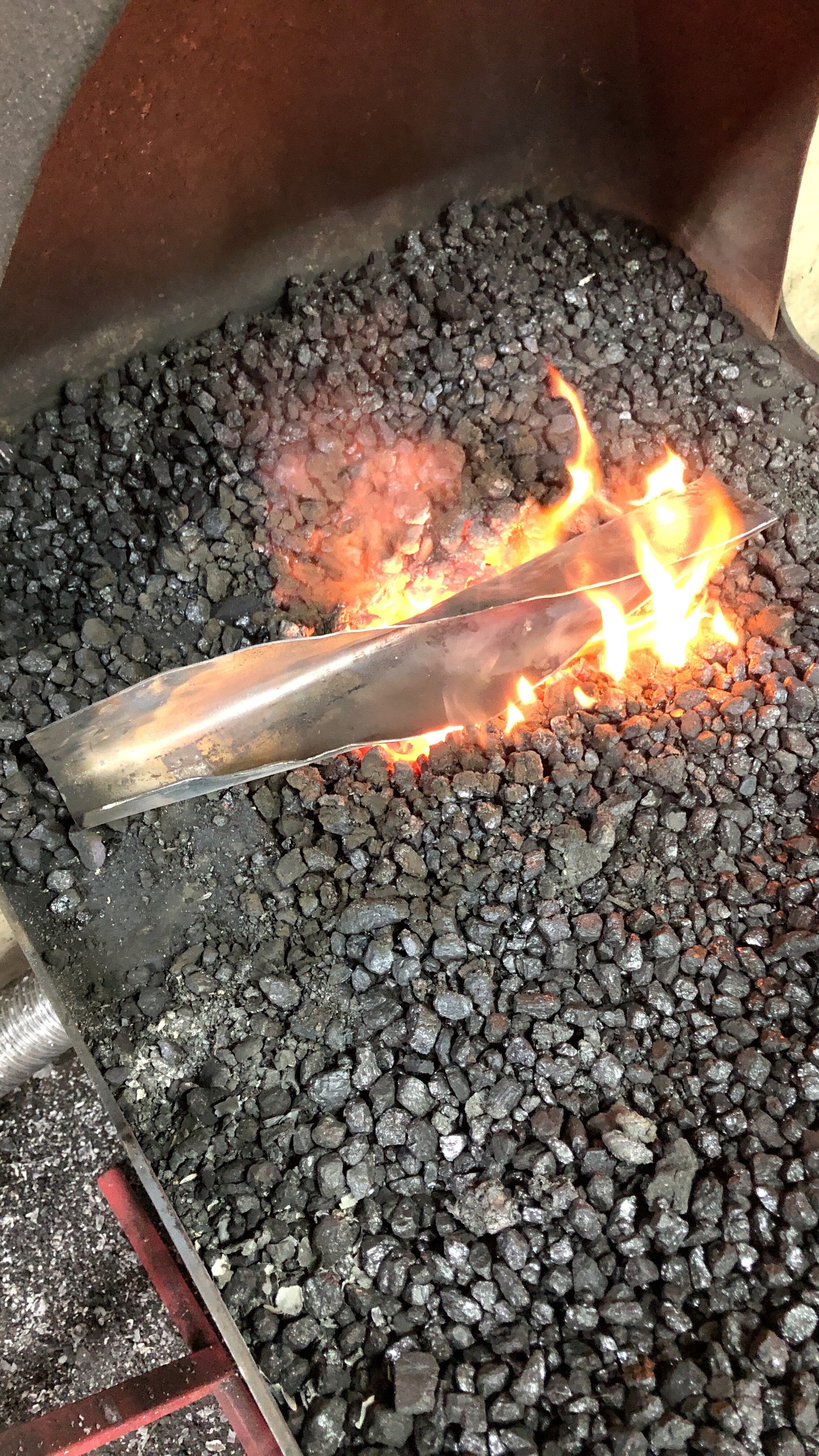

2. Coal tongs:

Took some reference pictures for a pair of coal tongs for the fire table at Pennsic, posting here to remind me to get to work on them:

3. New Hammer:

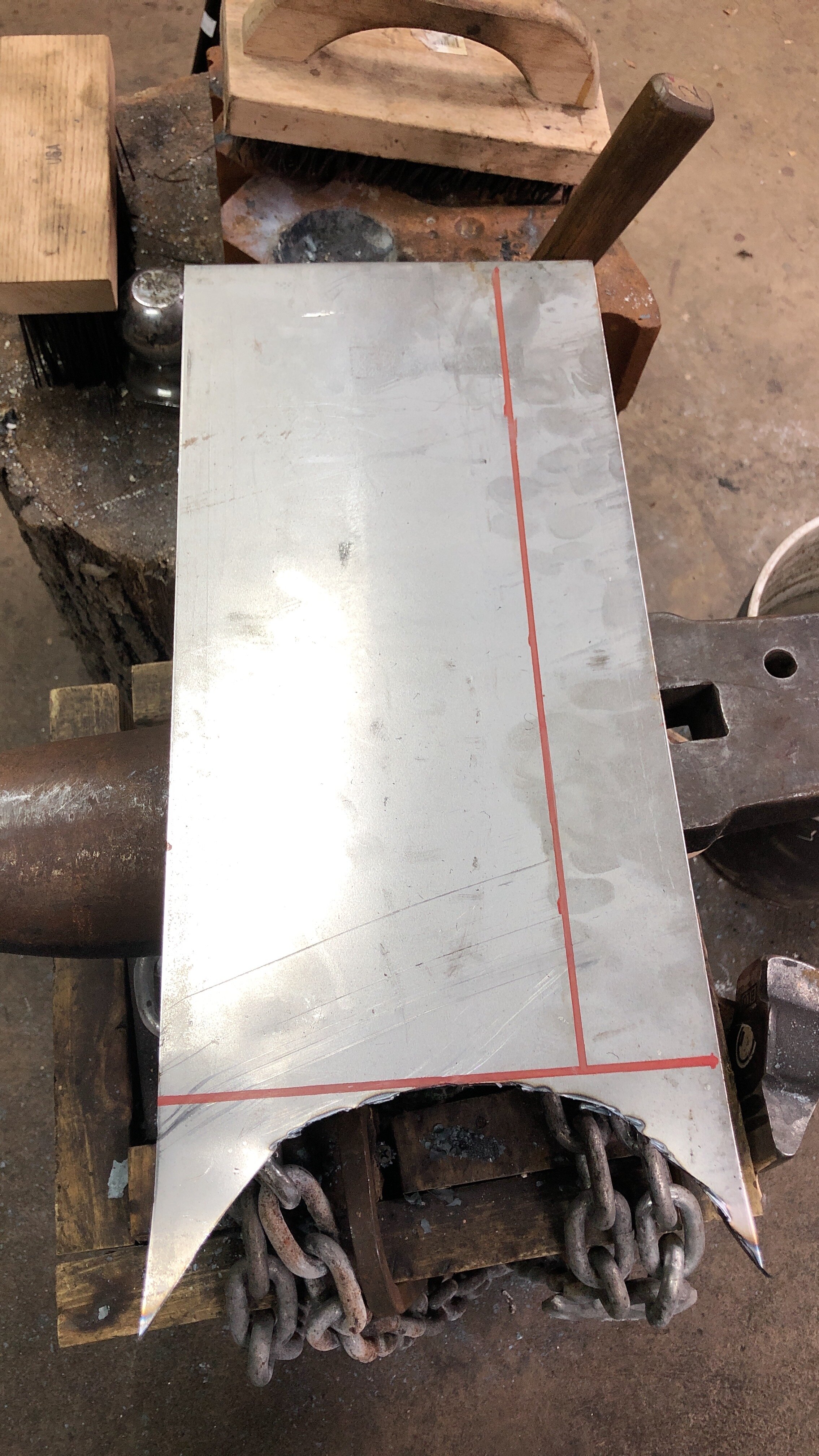

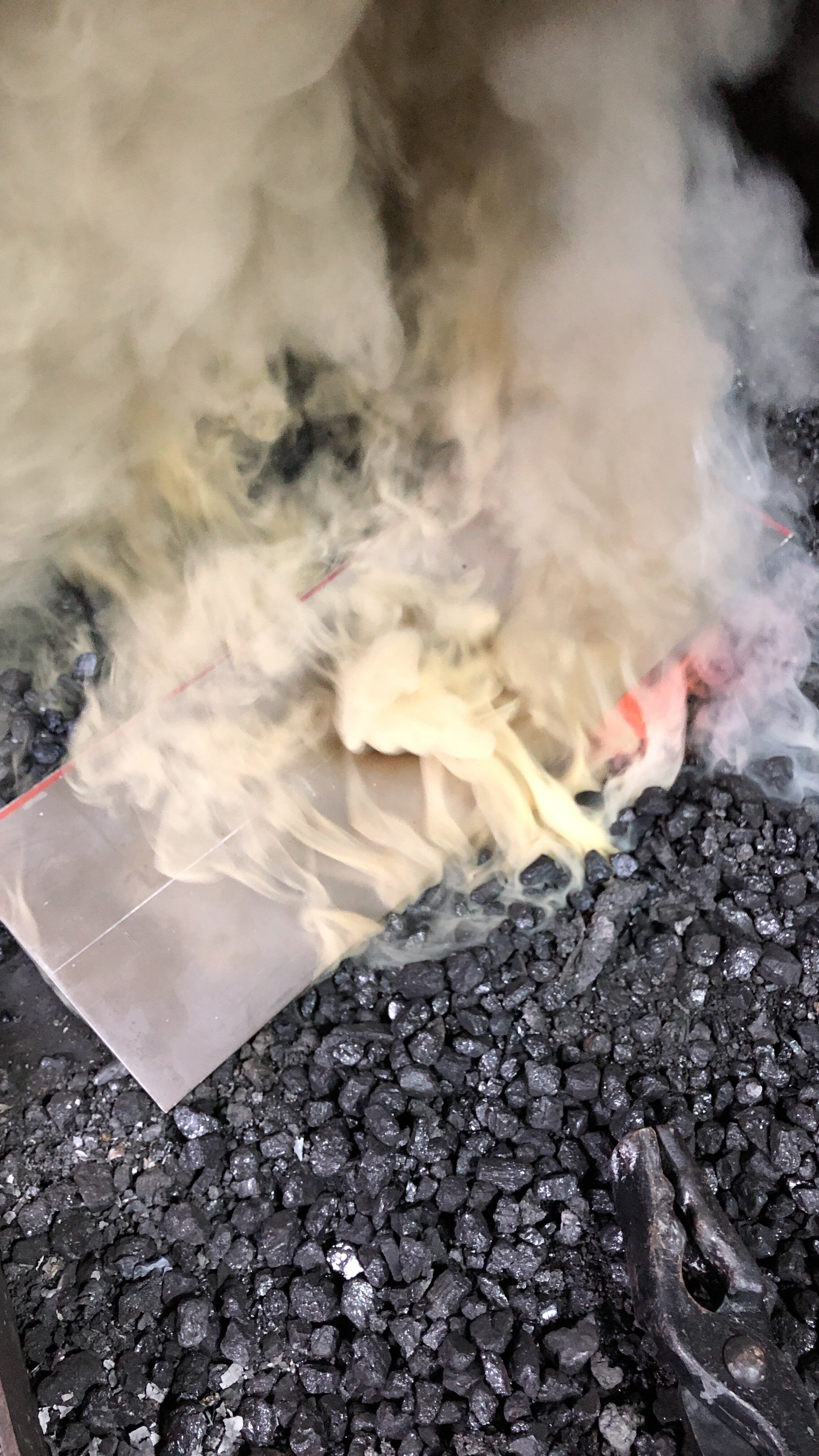

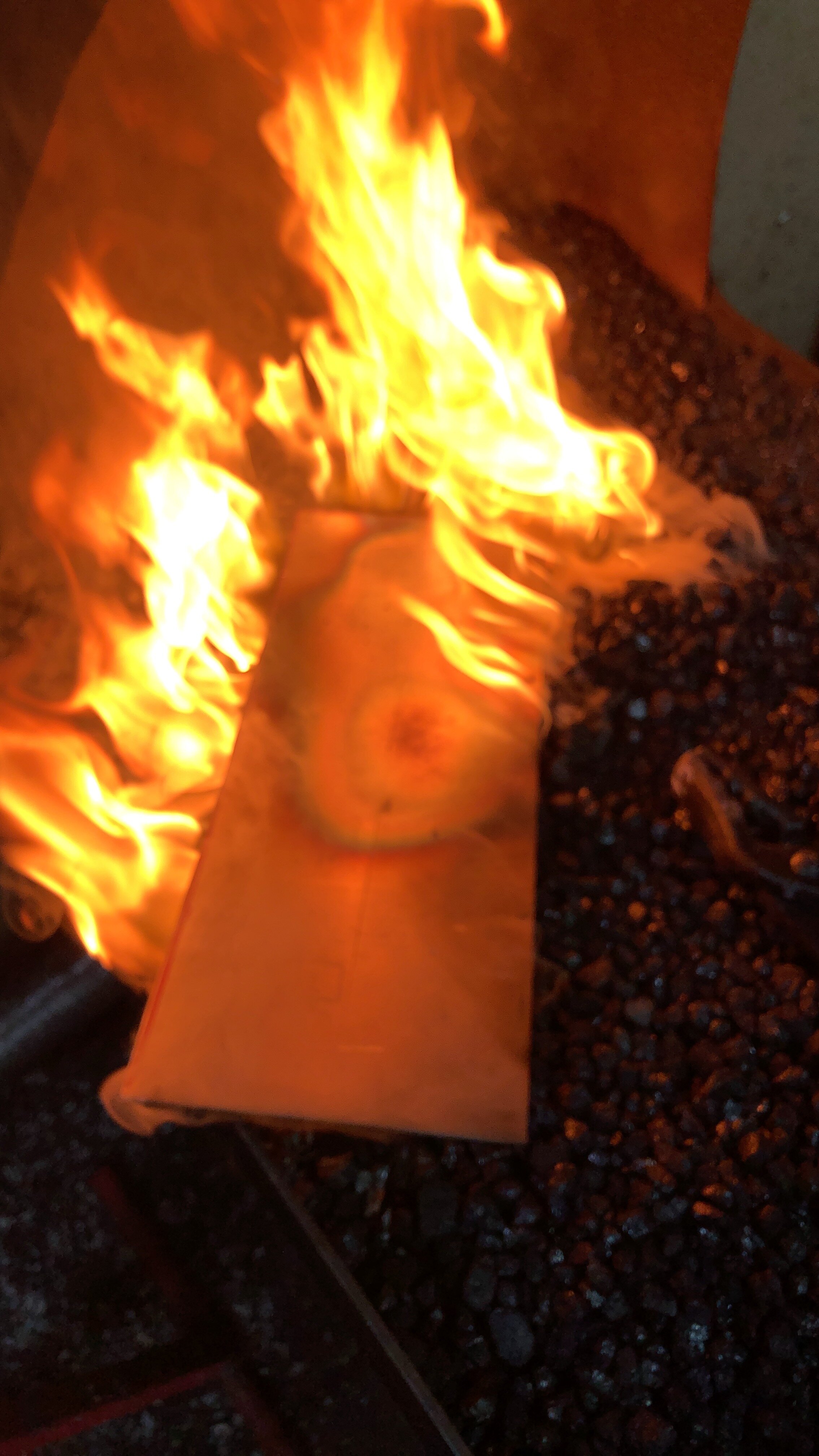

Started work on a new viking hammer. This one is going to be much bigger. Worked on it for a while, then got concerned with how much coal of my dwindling supply it was taking. The place where I normally get coal from has been shuddered for the foreseeable future, so I began to worry about running out. Here is the progress so far:

4. Oseburg cauldron

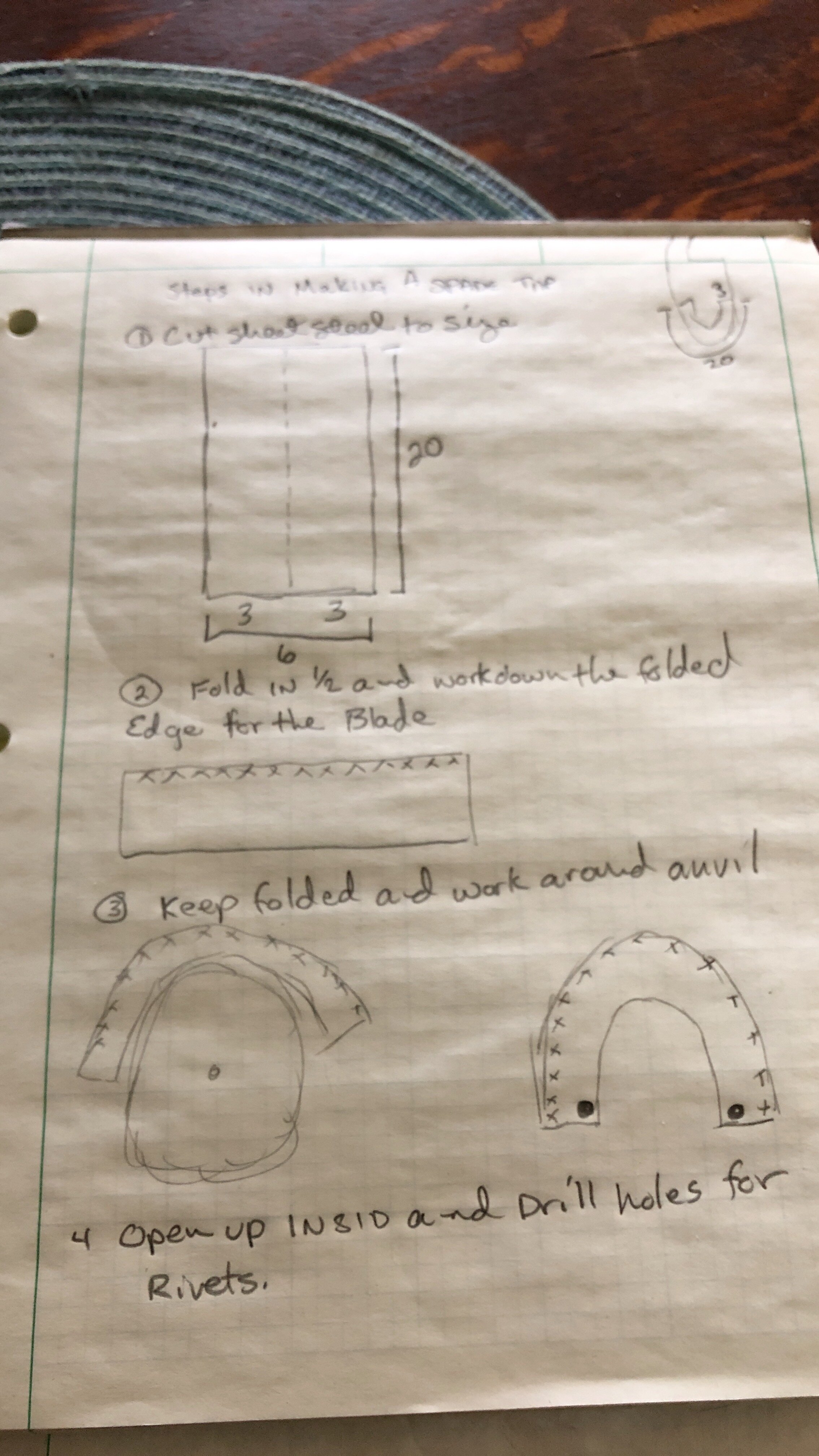

I have decided to try and make a forged and riveted cauldron similar to the one found in the Oseburg ship burial:

The first step is to make a cutting pattern. My 5th grade paper mache skill were brought to the forefront. Molded a cauldron to cut up in paper mace to work from. More on this project as I get back to it.

5. Jewelry Prep.

The other thing I have been working on is prepping silver for more projects in the future. Nothing in the works. Just replenishing silver sheet and wire stocks. Wire from a silver spoon and the sheet froma bunch of scraps from the bench:

Silver wire:

The wire has been rolled and will be run through a draw-plate when I next work on it.

6. For my final note: Coal had been obtained!!!!

Over 1/2 a ton of soft coal to feed the Grimmsfield forges. Found a great store in Maryland that sells coal and decided to stock up.

Well, that is what has been going on. Hopefully things will settle down soon and I can get back to regular A&S times.

Everyone please stay safe.