So on Sunday I proceeded to the next step in making the hood. This involved taking the now dry dark wool and making it spin-able. most of my projects in recent times have been done with viking combs to get the best of the wool and leave behind the inferior wool. Because of the limited amount of wool available, I elected to go back to standard combs. This would not create as nice of a yarn, but it allowed me to keep more of the roving. This will be the main activity of making the hood until most of the roving has been processed. The yarn will be stored on spools till a better estimation can be made of the amount. I hope to be able to ply the yarn into 2 ply for strength and uniformity, but that will depend on how much is produced.

View fullsize

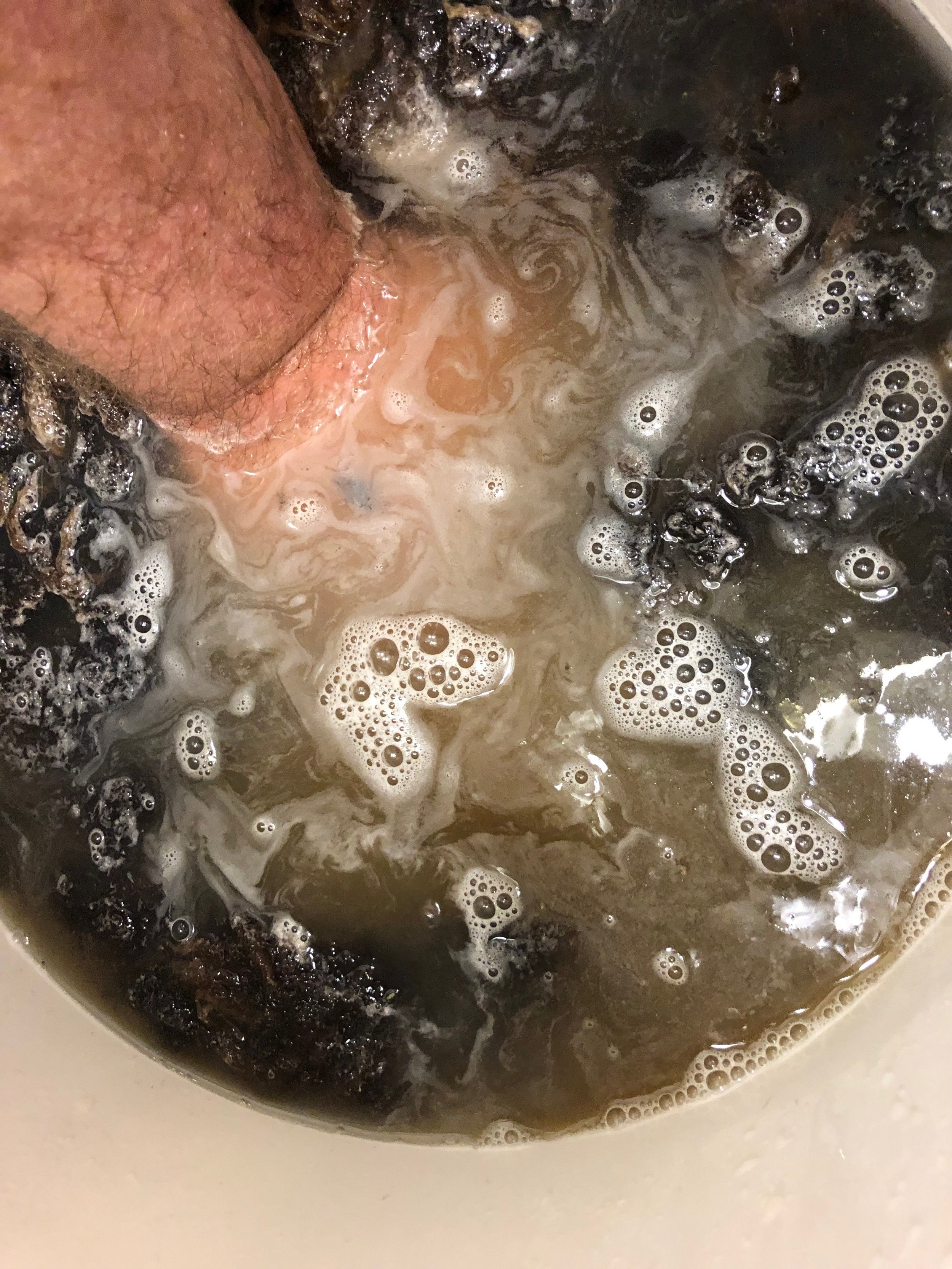

![The wool is finally Dry]()

The wool is finally Dry

View fullsize

![Loading the Combs]()

Loading the Combs

View fullsize

![First Pass]()

First Pass

View fullsize

![2nd Pass]()

2nd Pass

View fullsize

![Ready for spinning]()

Ready for spinning

View fullsize

![Preparing Multiple Batts]()

Preparing Multiple Batts

View fullsize

![Preparing the bobbins]()

Preparing the bobbins

View fullsize

![Preparing the wheel]()

Preparing the wheel

View fullsize

![Adjusting the tension]()

Adjusting the tension

View fullsize

![The First Wool is spun]()

The First Wool is spun

View fullsize

![Filling the Bobbin]()

Filling the Bobbin

View fullsize

![Working the wheel]()

Working the wheel